Woollen Felt application

Wool Felt has a versatile scope of application in almost all existing industries. Some examples of felt application are divided according to the following points:

Wool Felt can be utilised in various different densities for packaging and wrapping, and also it can be used for anything from filling empty space to providing highly effective absorption and suspension.

Wool felt can be used for polishing, semi-glossing, and removing scratches from metal, glass products and plastic surfaces, granite, and marble.

The fibreous and elastic structure of felt results in good absorption of vibrations.

Woollen felt has a porous structure and built-in capillary channels; which improves its absorbability and enhances the transfer of liquids. These absorbed liquids are slowly released through felt which serve as an efficient lubrication agent.

Due to its qualities, brilliant colours, and elegant appearance, woollen felt is an ideal material for various decoration and design purposes.

Due to wool fibres inherent quality of elasticity, enabling wool felt to be used as an excellent gasket material.

The porous quality of felt allows to absorb and prevent undesirable particles, like dust or carbon, etc. Woollen Felt is also capable of long-term resistance against the influence of water, oil, and other chemicals. Qualities like elasticity and durability enable wool felt to be used as “pressing mat – padding” in steel operation centres during scission and cutting. During this activity, felt also helps to clean and remove impurities from the steel roller.

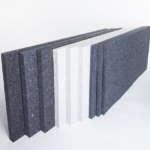

Woolen Felt reduces sound transfer, absorbs noise, which enables its use as a functional and decorative sound barrier.

Wool fibres and felt naturally keep the heat and absorb liquids making its use as good option for insulation.

Wool felt has good elastic structure, makes it an ideal material for the prevention of squeaking and whistling due to the friction of materials.